A Few Facts About Lug Nuts - Performance Plus Tire

Here are a few facts about wheel fasteners you should know before you bolt up your wheels on your ride.

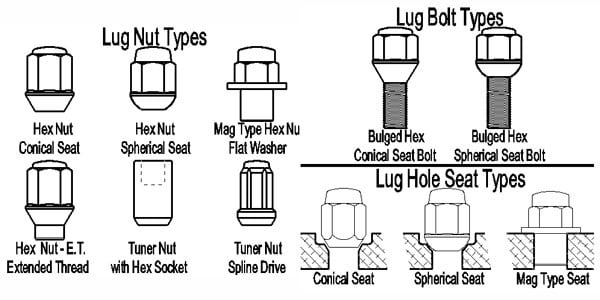

In order to match your lug nuts or bolts to your wheels, ensure:

- Proper Fastener Seat

There are 3 basic type fastener seats;

- Conical Seat – cone shape

- Spherical Seat – round or ball shape

- Flat Washer – commonly known as Mag Type

Be sure the fastener seat matches the seat in the wheel.

- Proper Thread Size.There are several different thread sizes used today by vehicle manufacturers;

- 12mm X 1.25

- 12mm X 1.5

- 12mm X 1.75

- 14mm X 1.5

- 14mm X 2.0

- 7/16? X 20

- 1/2? X 20

- 9/16? X 18

Two other things to remember; 1) do not put oil or lubricant on the threads of either the stud or lugs nuts/bolts, and 2) re-torque the lug nuts/bolts after 25-50 miles.

- Proper Thread Engagement.This is critically important. Make sure you have a minimum thread engagement of the diameter of the vehicle stud (as recommended by SAE). An example is, if the stud size of your vehicle is ½” then you will need a minimum of ½” of threads into the lug nut. If for some reason you do not have this minimum then it is recommended that you use an ET Type nut (Extended Thread) (see illustration). ET Type nuts are useful when using spacers (that will be another subject in a future TECH Stuff).

- Proper Torque (tightening)This is also very important. Over tightening lug nuts/bolts can fatigue the vehicle studs or lug bolts. Use the SAE recommended torque listed below as a guideline for passenger cars and light trucks;

12mm, 7/16?, 1/2? = 85 ft/lbs (+/- 5 ft/lbs)

14mm, 9/16? = 115 ft/lbs (+/- 5 ft/lbs)